Yiziphi izinhlobo zezinto zokubumba umjovo?

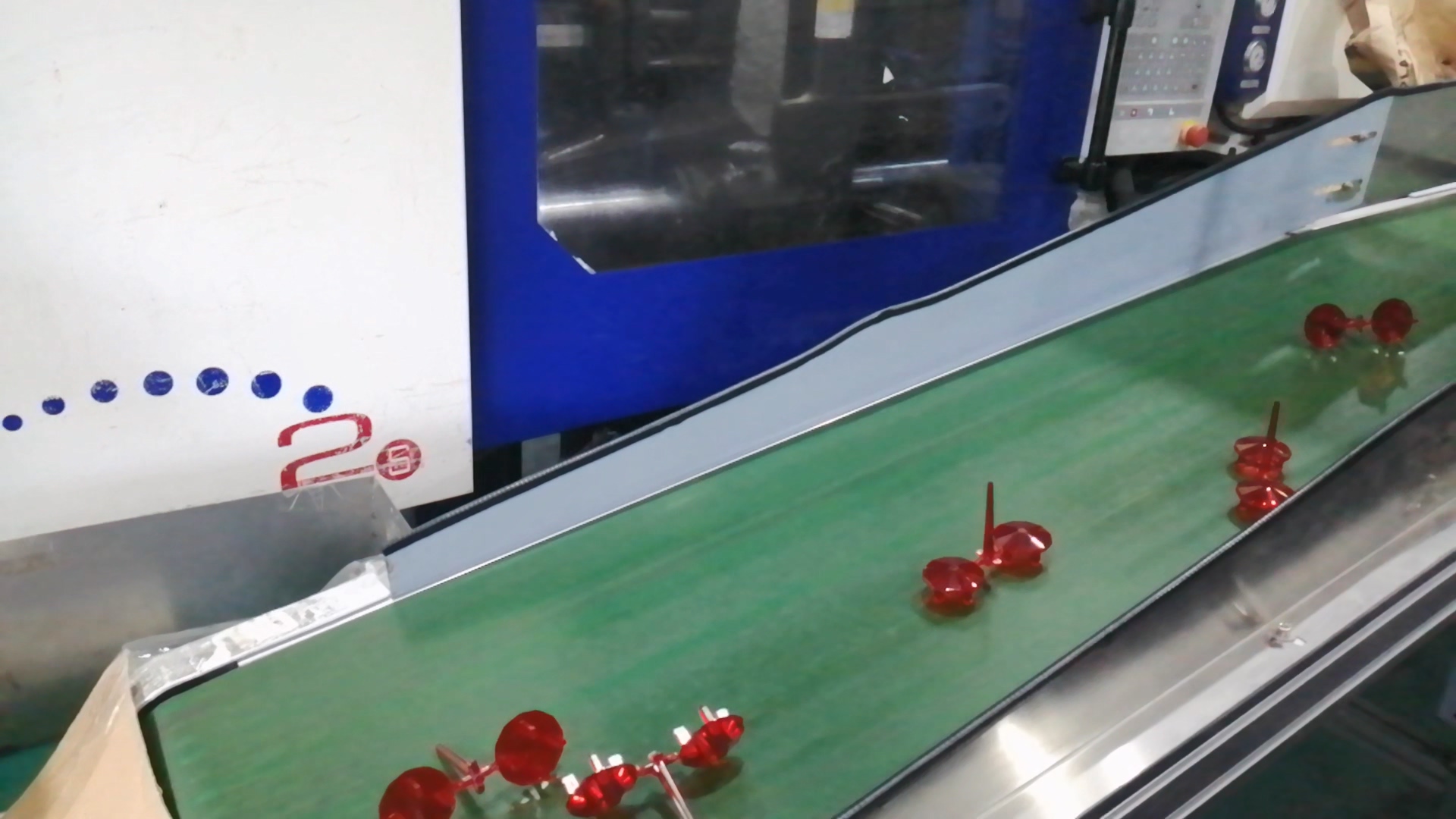

Ukubumba umjovo kuyinqubo yokukhiqiza ebandakanya ukujova izinto ezincibilikisiwe endaweni yokubumba ukuze kukhiqizwe umumo oyifunayo.Ukubumba umjovo kungasetshenziselwa ukwakha imikhiqizo ehlukahlukene, njengezingxenye zepulasitiki, izingxenye zensimbi, izisetshenziswa zezokwelapha, nokuningi.Nokho, akuzona zonke izinto ezilungele ukubumba umjovo.Sizoxoxa ngezinhlobo zezinto zokubumba umjovo kanye nezakhiwo zazo, izinzuzo, kanye nokubi.

Izinhlobo zezinto zokubumba umjovo

Kunezinhlobo eziningi zezinto zokubumba umjovo, kodwa zingahlukaniswa kabanzi ngezigaba ezine: ama-thermoplastic, ama-thermosets, ama-elastomer, nezinsimbi.

I-Thermoplastics

I-Thermoplastics izinto ezingancibilika ngokuphindaphindiwe futhi ziqiniswe ngokushisisa nokupholisa.Ziwuhlobo oluvame kakhulu lwezinto zokubumba umjovo, ezibalelwa ku-80% wemakethe.I-Thermoplastics inokuguquguquka okuphezulu, ukuqina, kanye nokusetshenziswa kabusha.Ezinye izibonelo ze-thermoplastics yilezi:

- I-Polyethylene (PE): Impahla ebiza kancane enokumelana okuhle namakhemikhali, umswakama, nomthelela.Isetshenziselwa kakhulu ukupakisha, iziqukathi, amathoyizi, namapayipi.

- I-Polypropylene (PP): Impahla enokuqina okuphezulu, amandla, nokumelana nokushisa.Isetshenziselwa izingxenye zezimoto, izinto zezokwelapha, ifenisha, nezinto zikagesi.

- I-Polyvinyl chloride (PVC): Impahla enokufakwa kahle kukagesi, ukungalawuleki komlilo, kanye nesimo sezulu.Isetshenziselwa izintambo zikagesi, amapayipi, izinto ezifakwayo, kanye nokubeka phansi.

- I-Polystyrene (PS): Into enokucaca okuhle, ukuqina, nokuzinza kwe-dimensional.Isetshenziselwa izinkomishi ezilahlwayo, amapuleti, izinto zokusika, nokupakisha.

- I-Acrylonitrile butadiene styrene (ABS): Okubalulekile okunamandla okuthonya okuhle, ukuqina, nokuqedwa kwangaphezulu.Isetshenziselwa izindlu, izigqoko zokuzivikela, amathoyizi, nezinsimbi zomculo.

- Inayiloni: Impahla enokumelana okuhle nokuhuzuka, ukumelana nokugqokwa, kanye nezakhiwo zemishini.Isetshenziselwa amagiya, ama-bearings, ama-bushings, nama-fasteners.

Ama-thermosets

Ama-Thermosets izinto ezibhekana nokusabela kwamakhemikhali lapho ishiswa futhi zakhe umumo unomphela ongakwazi ukuncibilika noma ukubunjwa kabusha.Ama-Thermoset anokuqina okuphezulu kwe-thermal, ukumelana namakhemikhali, namandla emishini.Ezinye izibonelo zama-thermosets zifaka:

- I-Epoxy: Into enamathela kahle kakhulu, i-insulation kagesi, nokumelana nokugqwala.Isetshenziselwa ukugqoka, ukunamathela, ama-laminates, nezinhlanganisela.

- I-Phenolic: Impahla enokumelana nokushisa okuphezulu, ukuncipha komlilo, nobulukhuni.Isetshenziselwa amaswishi kagesi, amasokhethi, amapulaki, nezibambo.

- I-polyester: Into enokuguquguquka okuhle, ukuqina, kanye nesimo sezulu.Isetshenziselwa imikhumbi yezikebhe, imizimba yezimoto, amathangi namapayipi.

- I-Urea formaldehyde: Impahla enezindleko eziphansi, ukuqina okuphezulu, nokuzinza okuhle kohlangothi.Isetshenziselwa amafindo, izinkinobho,

izibambo, kanye nefenisha.

Ama-elastomers

Ama-Elastomer ayizinto ezinganwetshwa noma zicindezelwe futhi zibuyele esimweni sazo sangempela lapho amandla esuswa.Ama-elastomers ane-elasticity ephezulu,

ukuqina, nokumunca ukushaqeka.Ezinye izibonelo zama-elastomer yilezi:

- I-Silicone: Into ekwazi ukumelana nokushisa okuhle kakhulu, ukumelana ne-ozone, kanye ne-biocompatibility.Isetshenziselwa izimpawu, ama-gaskets, amashubhu, kanye nemishini yezokwelapha.

- Irabha: Into ekwazi ukumelana nokuhuzuka, ukumelana nokukhathala, kanye nokuncibilika kokudlidliza.Isetshenziselwa amathayi, amabhande, amapayipi kanye nama-grommets.

- I-Thermoplastic elastomers (TPEs): Into ehlanganisa izici ze-thermoplastics kanye ne-elastomers.Ingacutshungulwa njenge-thermoplastics, kodwa inokuguquguquka nokunwebeka kwama-elastomers.Isetshenziselwa ukubamba, ama-bumpers, ama-mats, ne-seal.

Izinsimbi

Izinsimbi izinto ezinokusebenza okuphezulu, ukuminyana, nendawo encibilikayo. Zivamise ukujova esikhunjeni kusetshenziswa inqubo ekhethekile ebizwa ngokuthi i-metal injection molding (MIM).MIM ihlanganisa ukuhlanganisa izimpushana zensimbi nezibophezelo ukuze kwakhiwe isitokwe esingajova esitsheni. isikhunta.Ingxenye ebunjiwe ibe isishisiswa ukuze ikhiphe okuhlanganisayo futhi ifakwe isinki ukuze yakhe ingxenye yensimbi ecinene.I-MIM ingakhiqiza izimo eziyinkimbinkimbi ezinembayo ezinembayo, isiphetho esingaphezulu, kanye nezakhiwo eziwumshini.Ezinye izibonelo zezinsimbi ezingase zisetshenziselwe i-MIM yilezi:

- Insimbi engagqwali: Into enokumelana nokugqwala okuphezulu, amandla, nobulukhuni. Isetshenziselwa amathuluzi okuhlinza, izimila zamazinyo, ubucwebe, namawashi.

- I-Titanium: Okubalulekile okunesilinganiso esiphezulu samandla nesisindo, ukuhambisana kwe-bio-compatibility, kanye nokumelana nokushisa.Isetshenziselwa izingxenye ze-aerospace, okokusebenza kwezemidlalo, izifakelo zamazinyo, kanye nemishini yezokwelapha.

- Insimbi: Into enezindleko eziphansi, izakhiwo zikazibuthe, nokumelana nokugqokwa. Isetshenziselwa izingxenye zezimoto, amathuluzi wamandla, amagiya, namabheringi.

Isiphetho

Ukubumba umjovo kuyinqubo eguquguqukayo engakhiqiza imikhiqizo ehlukahlukene isebenzisa izinhlobo ezahlukene zezinto.Uhlobo ngalunye lwempahla lunezici zalo,

izinzuzo, kanye nobubi.Ngakho-ke, kubalulekile ukukhetha impahla efanele isicelo esikhethekile kanye nezidingo zedizayini.Ukubumba komjovo kungahlanganiswa nezinye izinqubo, njengokubunjwa kokufaka, ukugoqa ngokweqile, kanye nomjovo ohlangene, ukuze kwakhiwe izinto eziningi. noma imikhiqizo enemibala eminingi.Ukubumba komjovo kuyindlela esheshayo, ephumelelayo, futhi engabizi kakhulu yokwenza imikhiqizo yekhwalithi ephezulu.

Kuyini ukubumba umjovo?

Ukubumba umjovo kuyinqubo yokukhiqiza ekhiqiza izingxenye zepulasitiki ngokujova into encibilikisiwe esikhunjini.Inqubo iqukethe izigaba ezine eziyinhloko: ukubopha, umjovo, ukupholisa kanye nokukhipha.

I-clamping: Isikhunta sakhiwe ngama-halves amabili, abizwa ngokuthi i-cavity kanye ne-core, exhunywe kuyunithi yokubopha.Iyunithi yokubopha ibamba isikhunta sivaliwe ngaphansi kwengcindezi ngesikhathi sokujova nezigaba zokupholisa.Amandla okubamba ancike kusayizi nokuma kwengxenye, kanye nezinto ezisetshenzisiwe.

Umjovo: Impahla yepulasitiki, ngokuvamile isesimweni samapellets noma ama-granules, ifakwa emgqonyeni oshisayo, lapho incibilikiswa khona futhi ixutshwe yisikulufu esijikelezayo.Isikulufu siphinde sisebenze njenge-plunger, siphushela ipulasitiki encibilikisiwe esikhunjeni ngombhobho.Isivinini somjovo, ingcindezi kanye nezinga lokushisa kulawulwa ukuqinisekisa ukuthi impahla igcwalisa isikhunta ngokuphelele futhi ngokulinganayo.

Ukupholisa: Ipulasitiki encibilikisiwe ngaphakathi kwesikhunta iqala ukupholisa futhi iqine, ithatha isimo sengxenye.Isikhathi sokupholisa sincike kubukhulu kanye nejometri yengxenye, kanye nezakhiwo ezibonakalayo.Phakathi nalesi sigaba, isikhunta sihlala sivaliwe futhi singaphansi kwengcindezi yokuvimbela ukuncipha noma ukuguqulwa.

Ukukhipha: Ngemva kokuba ingxenye isipholile ngokwanele, isikhunta siyavulwa futhi ingxenye ikhishwe ngomshini okuthiwa i-ejector system.Isistimu ye-ejector ingaba izikhonkwane, izindwani noma amajethi omoya aphusha ingxenye esikhunjeni.Ingxenye ibe isikhishwa emshinini futhi ihlolwe ikhwalithi.

Ukubumba umjovo kuyinqubo eguquguqukayo futhi ephumelelayo engakhiqiza izingxenye eziyinkimbinkimbi nezisezingeni eliphezulu ngobuningi kanye nemfucuza ephansi.Isetshenziswa kabanzi ezimbonini ezahlukahlukene, njengezezimoto, ezokwelashwa, ezithengwayo, eze-elekthronikhi nokunye.

Yini ukubaluleka kanye neqhaza lesikhunta sokujova?

Ukubumba umjovo kuyinqubo yokukhiqiza esetshenziswa kabanzi engakhiqiza izingxenye zepulasitiki ezinobunjwa obuyinkimbinkimbi nokunemba okuphezulu.Ukubumba umjovo kuhilela ukujova ipulasitiki encibilikisiwe endaweni yesikhunta, lapho ipholisa khona futhi iqine ibe yisimo oyifunayo.Umgodi wokubumba uvame ukwenziwa ngensimbi noma nge-ceramic, futhi ungaklanywa ukukhiqiza izingxenye eziningi ngesikhathi esisodwa.

Ukubaluleka neqhaza lokubumba umjovo kubalulekile ezimbonini eziningi, njengezezimoto, ezokwelashwa, i-aerospace, ugesi wabathengi, nokunye.Ukubumba umjovo kunganikeza izinzuzo eziningi, njenge:

- Ukusebenza kahle kokukhiqiza okuphezulu: Ukubumba komjovo kungakhiqiza izingxenye eziningi ngesikhathi esifushane, ngokumosha okuncane nokulahlwa.Imishini yokubumba imijovo ingasebenza ngokuqhubekayo, futhi ingenziwa ngokuzenzakalelayo ukunciphisa izindleko zabasebenzi namaphutha abantu.

- Ikhwalithi ephezulu nokungaguquguquki: Ukubumba komjovo kungakhiqiza izingxenye ezinokunemba okuphezulu kwe-dimensional kanye nokuqedwa kwendawo, kanye nezakhiwo ezifanayo nokusebenza.Ukubumba umjovo kunganciphisa nokukhubazeka nokuhluka komkhiqizo wokugcina, ngokulawula izinga lokushisa, ingcindezi, kanye nesivinini senqubo yomjovo.

- Ukuguquguquka kwedizayini: Ukubumba komjovo kungakhiqiza izingxenye ezinejometri eyinkimbinkimbi, imininingwane eyinkimbinkimbi, nemibala eminingi noma izinto zokwakha.Ukubunjwa komjovo nakho kungamukela izinguquko ekwakhiweni noma ekucacisweni kwezingxenye, ngokushintsha imbobo yesikhunta noma ngokusebenzisa izinto zepulasitiki ezihlukile.

- Ukusebenza kahle kwezindleko: Ukubumba umjovo kunganciphisa izindleko eziphelele zokukhiqiza, ngokunciphisa ukusetshenziswa kwempahla, ukunciphisa ukuhlanganisa nokuqeda ukusebenza, nokwandisa ukuqina nokuphila kwezingxenye.

Ukubumba umjovo kuyinqubo yokukhiqiza eguquguqukayo nethembekile engahlangabezana nezidingo zezimboni nezicelo ezahlukahlukene.Kodwa-ke, ukubumba umjovo nakho kunezinselelo ezithile kanye nemikhawulo, njengokuthi:

- Ukutshalwa kwezimali okuphezulu kokuqala: Ukubumba umjovo kudinga izindleko eziphezulu zangaphambili zokuklama nokwenza umgodi wokubumba, kanye nokuthenga nokugcina umshini wokubumba umjovo.Umgodi wokubumba uvamise ukwenziwa ngendlela oyifisayo ingxenye ngayinye, futhi kungabiza futhi kudle isikhathi ukukhiqiza.

- Ukukhethwa kwezinto ezinomkhawulo: Ukubumba komjovo kungasebenzisa kuphela izinto ze-thermoplastic ezingancibilika futhi zigeleze ngaphansi kwezinga lokushisa eliphezulu nokucindezela.Ezinye izinto ze-thermoset noma izinto eziyinhlanganisela zingase zingakufanelekeli ukubumba umjovo, noma zingadinga izithasiselo ezikhethekile noma imithi yokwelapha ukuthuthukisa ukubumba kwazo.

- Umthelela wendawo: Ukubumba komjovo kungadala ukushisa okuningi kwemfucuza kanye nokukhishwa kwegesi ngesikhathi sokuncibilika nokupholisa kwempahla yepulasitiki.Ukubumba umjovo kungaphinda kukhiqize udoti wepulasitiki ophuma ezintweni ezivuzayo eziphuma emgodini wesikhunta noma akheke emaphethelweni engxenye.Le mfucumfucu idinga ukugaywa kabusha noma ilahlwe ngendlela efanele, ukuze kwehliswe umthelela wazo kwezemvelo.

Ukubumba umjovo kuyinqubo eyinkimbinkimbi futhi eguquguqukayo edinga ukuhlela ngokucophelela, ukuklama, nokwenza kahle.Onjiniyela bokubumba umjovo badinga ukubheka izinto eziningi, njenge:

- Ukukhethwa kwempahla: Ukukhethwa kwezinto zepulasitiki kuthinta izakhiwo, ukusebenza, ukubukeka, kanye nezindleko zengxenye yokugcina.Izinto zepulasitiki kufanele zihambisane nezidingo zomsebenzi wengxenye, indawo ezungezile, ubuhle, nokuqina.Izinto zepulasitiki kufanele futhi zibe nokugeleza okuhle, ukuzinza, ukuncipha, nokuhambisana nomgodi wokubumba.

- Idizayini yesikhunta: Ukwakheka kwesigxobo sesikhunta kunquma ukuma, ubukhulu, ikhwalithi, kanye nobunkimbinkimbi bengxenye yokugcina.Isikhunta kufanele sibe nemishini eyanele yokukhipha umoya, yokupholisa, yokukhipha, neyokubamba ukuze kuqinisekiswe inqubo yokujova ebushelelezi nephumelelayo.I-mold cavity kufanele futhi ibe nama-engeli okusalungiswa afanelekile, ubukhulu bodonga, ukubekezelelana, kanye nokuqedwa kwendawo, ukuvimbela ukukhubazeka nokukhubazeka engxenyeni yokugcina.

- Amapharamitha wenqubo: Izilungiselelo zenqubo yomjovo zithinta ukuziphatha kokugeleza, izinga lokupholisa, ukusatshalaliswa kwengcindezi, kanye nokucwebezela kwezinto zepulasitiki.Imingcele yenqubo kufanele ilungiswe ukuze kwandiswe ukugcwaliswa, ukupakisha, ukubamba, ukupholisa, nokukhipha izigaba zenqubo yomjovo.Imingcele yenqubo kufanele futhi iqashwe futhi ilawulwe ukuze kugcinwe ukuvumelana kanye nekhwalithi emkhiqizweni wokugcina.

Ukubumba komjovo kuyinqubo yokukhiqiza enamandla nedumile engakha izingxenye zepulasitiki zekhwalithi ephezulu ezinobumo nemisebenzi ehlukahlukene.Ukubumba umjovo kudlala indima ebalulekile ezimbonini eziningi ezithembele emikhiqizweni yepulasitiki ngokusebenza kwazo kanye nenzuzo.Ukubumba umjovo nakho kuyinqubo eyinselele nethuthukayo edinga ukusungulwa njalo nokuthuthukiswa ukuze kuhlangatshezwane nezidingo ezishintshayo kanye nokulindelwe ngamakhasimende.