Ngu-Andy wase-Baiyear factory

Kubuyekezwe ngoNovemba 5, 2022

Mayelana nokwethulwa kwezinyathelo ezithile zokukhiqiza zesikhunta, sikuhlukanise kwaba yizindatshana ezi-2 ukuze sethule, lesi sihloko sesibili, okuqukethwe okubalulekile: 1: Isikhunta Esijwayelekile Somjovo Wepulasitiki 2: Ukwenza Isikhunta Sefekthri 3: Isikhunta Somjovo Wepulasitiki 4: Isikhunta somjovo onembile 5: umenzi we-plastic mold die 6: ukwakheka kwesikhunta sokubumba umjovo 7: ukwenza isikhunta nokuphonsa 8: inqubo yokwenza isikhunta

7. Ukucima isikhunta sangaphakathi

(1), sebenza ngaphambi kokucisha

a) Ukubhoboza imbobo yombhobho: Bamba imbobo yenobhothi endaweni engaphezulu yokudayela ngokwezidingo zomdwebo.Lapho ubhoboza imbobo ye-nozzle endaweni engaphezulu, naka isikhungo esifanayo nembobo engezansi.

b) Ukubhoboza imbobo ye-shunt cone: Bamba imbobo ye-shunt cone phakathi nendawo yomgijimi ophansi we-die ngokwezidingo zomdwebo, bese ulungisa ikhoni ye-shunt, bese ubhoboza imbobo ye-thimble kuyo.

c) Ukumba imbobo yamanzi: Ngokuvumelana nezidingo zesithonjana, vula imbobo yamanzi (amanzi okupholisa) ohlangothini lwesikhunta sangaphakathi.

d) Bamba bese ucindezela imbobo yokulungisa (imbobo eyimpumputhe) endaweni ehlangene yesikhunta sangaphakathi kanye nohlaka lwesikhunta.

e) Uma kunezinaliti kusikhunta sangaphakathi, izimbobo yenaliti kufanele zibhojwe.

(2), bhoboza imbobo yethonga

Iphinikhodi ye-ejector iyingxenye ebalulekile yomsebenzi wemishini wesikhunta.Umsebenzi wawo ukuhlukanisa umkhiqizo kusuka kumongo wesikhunta ngokusebenzisa isenzo se-ejector somshini kabhiya, ukuze kuzuzwe umphumela wokukhipha konke.Ukunemba kokucubungula kwephinikhodi ye-ejector kuthinta ngqo ikhwalithi yesikhunta.kanye nempilo yesevisi.Izidingo zenqubo:

a) Ukuma kwembobo yethoni kufanele kucutshungulwe ngokuya ngezidingo zomklamo zizonke zomkhiqizo, ukugwema izindonga ezincanyana kanye nezingxenye ezithinta ukubukeka ngangokunokwenzeka.Ukuze ugweme isibambo sikabhiya (umthambeka) endaweni yoshintsho, kanye nenaliti ephukile ngesikhathi sokukhiqiza, kufanele isetshenziswe ngaphambi kokubhoboza imbobo ye-thimble.Bamba ichopho lokubhoboza lengxenye encane ukusuka ngezansi, bese usebenzisa ichopho lokubhoboza lengxenye enkulu ukuze ubhoboze usuka ohlangothini olungemuva.

b) Lapho wenza izimbobo zomshini, hlola ukuma phakathi kwezimbazo zemishini yokubhola neyokugaya esetshenziswa kanye netafula lokusebenza.

c) Imbobo yethimbo kufanele ishiywe nomphetho ngesikhathi sokucutshungulwa, ukuze kuqinisekiswe ukushintshwa komshini phakathi kwembobo nethiphu ngemva kokuphinda kufakwe into ephindayo.Uma iqine kakhulu, imbobo nethimble izosha ngesikhathi sokukhiqiza;Kukhona imingcele.

d) Uma ubhoboza imbobo yethimble, kufanele kuqinisekiswe ukuthi imbobo yokuthutha amanzi ngeke ibhojwe.

e) Lapho ubhoboza izimbobo zethonsi ngaphansi kuka-1.5mm, ubude bengxenye yoshintsho kufanele bugcinwe buphakathi kuka-20mm no-30mm ukuze kugwenywe izimbobo ezingenamuntu, bese ingxenye engenalutho (igebe phakathi kwethonjana nembobo yethonga) kufanele kusetshenziwe.Imbobo yokugwema imbobo kufanele ibe mkhulu ngo-0.5mm kunembobo yokushintsha.Uma inkulu kakhulu, ithoni elide kulula ukugoba nokuphuka.

(3), ukucisha isikhunta sangaphakathi

Ngemuva kokuthi isikhunta sangaphakathi sihle, sithunyelwa esitshalweni sokushisa ukushisa ukuze kucinywe, ukuze isikhunta sangaphakathi sikwazi ukuhlangabezana nezidingo zobunzima.

8. Drop ifreyimu

(1), lahla uhlaka

Ngemva kokuba isikhunta sangaphakathi sesicishiwe, sifakwa ohlakeni lwesikhunta ukuze kuhlolwe ukuhlanganisa.Kulokhu, kuyadingeka ukugaya futhi unciphise umkhawulo ohlangene wefreyimu yesikhunta kanye nesikhunta sangaphakathi, ukuze isikhunta sangaphakathi singawela ngokuphelele kuhlaka lwesikhunta futhi ukuhambisana kuvamile.

(2) Bamba izimbobo zokulungisa isikhunta sangaphakathi ohlakeni lwesikhunta

Krurula insiza yesikhungo sokuma embobeni yesikulufu sesikhunta esingaphakathi, bese ucindezela isikhunta sangaphakathi kuhlaka lwesikhunta, ukuze ithuluzi eliyinsiza limake isikhungo sembobo kuhlaka lwesikhunta.Bese ukhipha isikhunta sangaphakathi futhi ufinye amathuluzi asizayo.Gcoba izimbobo kuhlaka lokubumba ngokwezimpawu zokubhoboza, bese ekugcineni uphendulela uhlaka lwesikhunta bese ubhoboza izimbobo.

9. Hlehlisa umugqa futhi

Lesi sinyathelo senziwa ngemva kokuba isikhunta sangaphakathi sehlisiwe, futhi inhloso ukuhlola ukulingana kwezinhlangothi ezimbili zendawo yokusebenza yomugqa kanye nesikhunta sangaphakathi.Faka upende obomvu ezingxenyeni ezisemaceleni zesikhunta sangaphakathi nendawo yomugqa, faka indawo yomugqa, bese ucindezela indawo yomugqa endaweni.Ingxenye ephambene yomugqa kufanele iphrinte ngokuphelele ngopende obomvu, ngaphandle kwalokho kufanele iphuculwe, ilungiswe, futhi ihlolwe ngokuphindaphindiwe kuze kube yilapho upende obomvu uphrintiwe ngokuphelele.

10. Ukuvala umugqa

Ngemuva kokuthi umugqa umuhle, uyacishwa ukuze uhlangabezane nezidingo zokuqina.

11. Isihlalo sokucindezela (inkukhu egobile)

(1), icubungula ukuma kwerowu

Ngokwezidingo zesithonjana nezimo zobuchwepheshe, indiza ethambekele icutshungulwa endaweni eshelelayo yendawo yomugqa.

(2), isihlalo sokucindezela

a) Ukuthambeka komugqa kanye nosayizi wefreyimu engaphezulu yohlaka lwesikhunta.

b) Geza izimbobo zokubeka phezu kohlaka olungaphezulu lokufa kanye nesihlalo sokucindezela ngokuya ngokuthambekela kwethambeka lomugqa kanye nendawo yomugqa, bese ulungisa isihlalo sokucindezela phezu kohlaka lwesikhunta olungaphezulu.

c) Bomba imbobo ye-bevel endaweni yomugqa, futhi imbobo ye-bevel kufanele ibe yi-2 degrees encane kune-bevel.

d) Bamba izimbobo zokuma ezibevelelwe ku-fayizi engenhla ngokuma kanye nokuthambekela kwezimbobo eziboshiwe ezibhojwe endaweni yomugqa, bese ufaka imiphetho eboshwe ukuze uhlole ukuqondanisa.Imbobo ye-hypotenuse ngokuvamile iyimindeni emi-2 emikhulu kune-hypotenuse.

12, imodeli iyonke

Ngemuva kokuthi isikhunta sangaphakathi, indawo yomugqa, inaliti yokufaka, kanye nohlaka lwesikhunta konke kufaniswe, isikhunta esiphezulu nesiphansi siyahlanganiswa ukuze senze isikhunta, futhi isikhunta sangaphakathi esingenhla nangaphansi, imigqa kanye nokufaka kuhlolwe ngopende obomvu., Lungisa ifosholo lize lifakwe ngokuphelele.

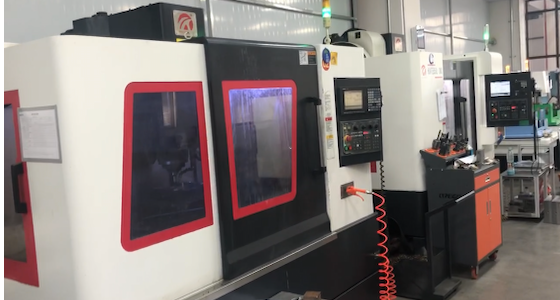

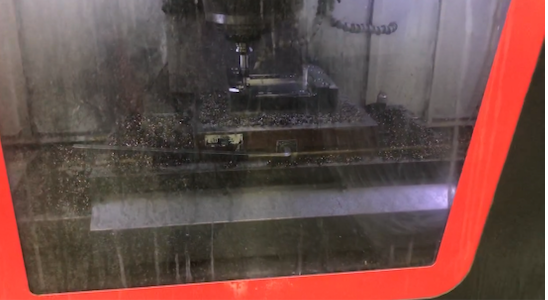

13. EDM machining

I-EDM isekelwe kumgomo we-EDM.Lapho owesilisa wethusi nesiqeshana sokusebenza kusondelene, amandla kagesi e-inter-electrode azobangela ukuthi i-electrolyte i-ionize futhi iphule endaweni eseduze kakhulu phakathi kwama-electrode amabili ukuze kwakhe ukukhishwa kwenhlansi, okuholela esilinganisweni esikhulu samandla okushisa ngaso leso sikhathi. ekhiqizwa esiteshini senhlansi, okwenza insimbi incibilike kancane, iphinde ihwamuke, futhi ihwamuke ukuze igugule insimbi.Ingasetshenziselwa noma iyiphi into eqhutshwayo ukucubungula noma iyiphi impahla yensimbi eqinile, ephukayo, ethambile, enamathelayo noma ephezulu encibilika, okuhlanganisa insimbi efakwe ukushisa nama-alloys, ama-electrode amathuluzi (i-copper male ) kanti i-workpiece ingaphansi kokugqwala kukagesi ukukhiqiza ukugqwala. (umhwamuko nokuqinile).Ukugqwala kukagesi kowesilisa wethusi kuzodala ukulahleka kwe-electrode, futhi ukugqwala kukagesi kwendawo yokusebenza kuzolenza lihlangabezane nezidingo zokunemba zokwakheka.

Izidingo zenqubo:

(1) Bophela owesilisa wethusi ngokuqinile ku-spindle chuck yethuluzi lomshini, futhi ulungise indawo yereferensi ukuze ulenze lihlangabezane nezimfuneko zokunemba komshini.Amanye amaduna ethusi anezinhlangothi ezintathu ezinkulu futhi azacile kulula ukuwohloka futhi agobe ngesikhathi sokucutshungulwa, futhi kufanele amiswe ngokulinganayo kwabesilisa bekhopha abanezinhlangothi ezintathu ngesiqeshana sokulungisa sohlobo lwe-tripod.

(2) Faka i-workpiece etafuleni lomshini bese ulungisa ukunemba kwereferensi.

(3), ngokuya ngezidingo zokucubungula zengxenye ngayinye ye-electro-rosion processing.

14. Ukupholisha (i-die-saving)

Ukupholisha isikhunta ukucubungula imbobo yesikhunta kanye nokuqedwa okuyisisekelo kuya ezidingweni zokubukeka komkhiqizo.Kuyingxenye ebalulekile yenqubo yokukhiqiza isikhunta.Izinga lokunemba kokupholisha lithinta ngqo ikhwalithi yokubukeka yomkhiqizo.Ziningi izindlela zokupholisha, njengokupholisha ngomshini (ultrasonic), ukupholisha umshini wokugaya nokupholisha ngesandla.Ukupholisha okuvame ukusetshenziswa kakhulu ngaphansi kwezimo ezijwayelekile, izidingo zayo zenqubo:

(1) Lapho upholisha futhi ulondoloza isikhunta, kufanele ubone futhi uqonde izidingo zangaphakathi nezangaphandle zomkhiqizo.

(2) Ngaphambi kokupholisha, sebenzisa ifayela ukuze unciphise imikhondo engaphezulu eshiywe ukucutshungulwa okuhlukahlukene.

(3) Ngokwesisekelo sokunquma nge-whetstone, sebenzisa i-sandpaper ukusuka kokumahhadla ukuya kokucolile ukuze wonge ukukhanya ngokwezidingo zomkhiqizo.

(4) Ngemikhiqizo enezidingo ezikhethekile, njengezingxenye ezibonisa ngale, kufanele ipholishwe ngokunamathisela okunameka.

(5) Umsebenzi opholishiwe kufanele ube nemigqa ecacile, ekhanyayo futhi eshelelayo, futhi ingabi namakhona ayindilinga emihlathini.

15. Ngethunjana

Bomba uhlaka olungezansi lwe-die kanye nepleti yenaliti yobuso ngembobo yephini yokukhipha kusikhunta esingaphansi esingaphakathi, bese ugaya imbobo yephini yeshubhu embotsheni yenaliti yobuso, bese ufaka iphinikhodi yokukhithiza epuleti yenaliti yobuso, elingezansi. uhlaka lwesikhunta kanye nesikhunta sangaphakathi esiphansi.Qinisekisa ukuthi iphinikhodi yokukhipha ishaywa ngokuphuma kwesikhunta sangaphakathi esingenhla, bese ufaka iphinikhodi ejector emaphethelweni embobo yephini yokukhipha yepuleti lephini lobuso, bese ucindezela iphinikhodi ejector endaweni.

16. Imodi yokuhlola

(1), ifakwe izesekeli ezifana nomzimba wenkemba, futhi ihlanganise isikhunta.

(2) Faka isikhunta emshinini kabhiya ngokwezinqubo zokusebenza zomshini kabhiya ukuze wenze izingxenye zikabhiya.Ukuhlolwa kwesikhunta kuyingxenye ebalulekile yenqubo yokubumba.Ukuze unqume ngokunembile ikhwalithi yesikhunta ngendlela yezingxenye zikabhiya, ingcindezi yokubopha, ingcindezi yomjovo, izinga lokushisa lokushisa kagesi, izinga lokushisa lomlilo elincibilikayo, njll. Kumele kulungiswe ngaphambi kokuhlolwa kwesikhunta, futhi isikhathi ngasinye.Yenza irekhodi lesilingo.Indawo yokusebenzela yokuhlola ubhiya akumele ingabi nama-streaks abandayo, i-batch front, ingabi nokuncipha, ingabi namabhamuza phakathi kuka-15%, ingabi nemihlathi esobala nezimpawu zamanzi, futhi ingaphezulu libushelelezi futhi isikhunta sibushelelezi.Uma ihluleka ukuhlangabezana nezidingo, kuyadingeka ukuyilungisa bese uzama futhi.

17. Ukuguqulwa

Ngokwemiphumela yokuhlolwa, isikhunta siyasikwa, futhi isikhunta silungiswa ngokuvumelana nezidingo zamakhasimende kanye nezidingo zomhlangano.Ukuguqulwa kwesikhunta kuyingxenye ebalulekile yokukhiqiza isikhunta.Inhloso yokukhiqiza isikhunta ukukhiqizwa ngobuningi.Ijubane nokunemba kokuguqulwa kwesikhunta kuthinta ngqo ikhwalithi yomkhiqizo nenqubekelaphambili yokukhiqiza.Umsebenzi wokushintsha isikhunta ukuqinisekisa ukuthi ukusayina (ihhovisi lokuthengisa) elihlanganiswe ngaphandle kwamathuluzi asizayo okulungiswa kokuxhumana kuhlangabezana nezimfuneko zemakethe (ikhasimende) kanye nebhokisi lokudlidliza (ngaphandle kwezidingo zokuhlobisa ngaphezulu).Ihhovisi lokufakwa kukanjiniyela lizothunyelwa ehhovisi lekhasimende ngemva kokubuyekezwa kwangaphakathi.Ngokwenkinga yesikhunta uqobo, unjiniyela uzohlinzeka ngolwazi lokuguqulwa kwesikhunta ngokuya ngezidingo zomhlangano kanye nezidingo zamakhasimende.Izinto zokuguqulwa kufanele zibhalwe ngokucacile futhi ulimi luqondakala kalula futhi ngaphandle kokungaqondakali.Izidingo zedatha kufanele zicace futhi ziphelele, amaphuzu okubhekisela kufanele amakwe kulabo abanezidingo zesikhundla sangaphambili nangemuva, futhi isibalo kufanele senzelwe labo abanezidingo zomumo.Lapho unjiniyela ehambisa imininingwane yokuguqulwa kwesikhunta kubasebenzi abalungisa isikhunta, kufanele achaze ngokucacile amaphuzu ayinhloko okuguqulwa kwesikhunta, izingxenye okufanele zilungiswe, izimfuneko zokuguqulwa, kanye nenjongo yokuguqulwa.Ngemuva kwesinqumo somuntu, singabulawa ngokulandela okuhle kakhulu.

18. Ukukhishwa kwesikhunta

Ngemva kokuba isikhunta sesilungisiwe, sihloliwe, sasayinwa, futhi ikhwalithi ihlangabezana ngokugcwele nezidingo zekhasimende kanye nezidingo zokuhlanganiswa kwamathoyizi, isikhunta singanikezwa futhi sifakwe ekukhiqizeni.

Oxhumana naye: Andy Yang

What's app : +86 13968705428

Email: Andy@baidasy.com

Isikhathi sokuthumela: Nov-29-2022